|

This is an archived site. You can find our new website HERE.

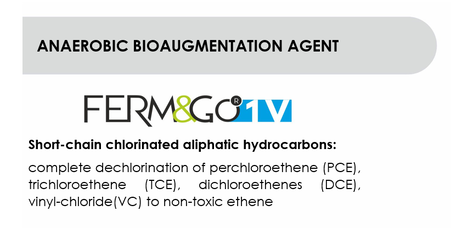

Our company currently has three certified bioaugmentation agents, of which Ferm & Go 1V can be applied for bioremediation of short-chain chlorinated hydrocarbons, Ferm & Go 2PT and 3P for aliphatic and aromatic hydrocarbons.

|

Dehalococcoides - which is present in uniquely high cell count number in our bioaugmentation agent - is the only known group of microorganisms capable of dechlorinating short-chain chlorinated aliphatic hydrocarbons (perchloroethene, trichloroethene, dichloroethenes, vinyl-chloride) to non-toxic ethene through reductive dechlorination under anaerobic conditions. Our product contains 10E6 vynil-chloride reductase subunit A (vcrA) gene copies/ml.

|

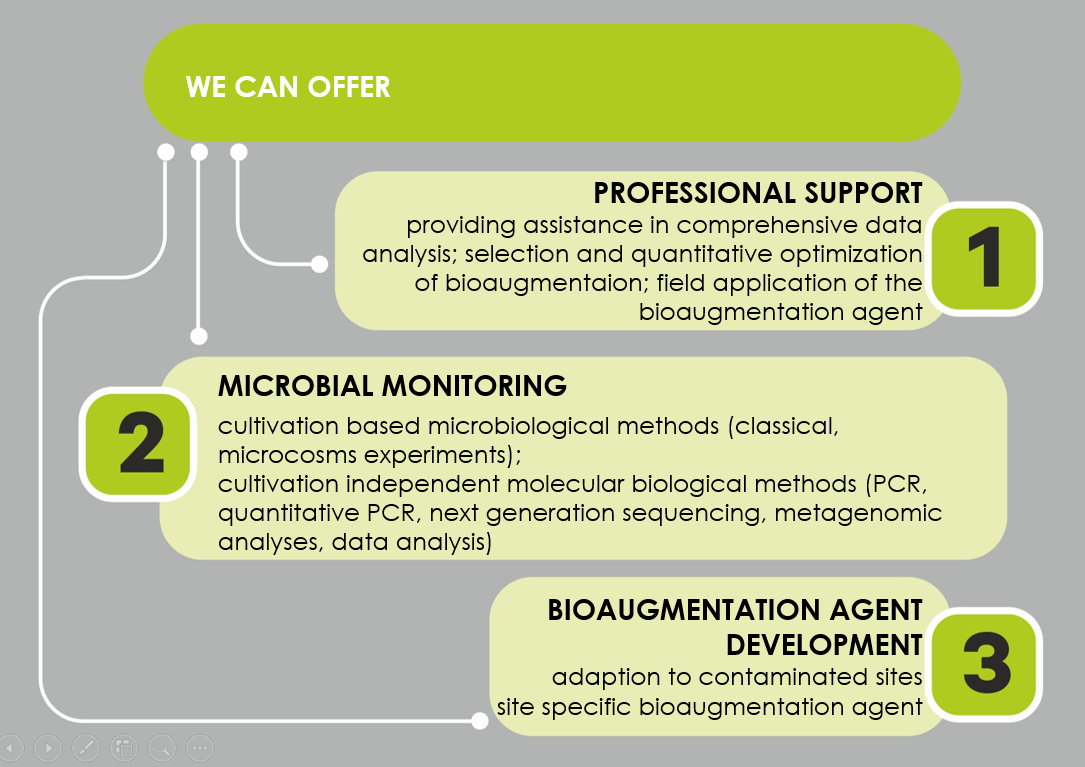

Taking into consideration the oxygen sensitivity of the organohalide-respiring microorganisms, bioaugmentation agent is dosed into properly anaerobic groundwater or soil using special dispensing containers. On request, our Team can provide professional assistance to remediation companies and specialists in the appropriate application of the bioaugmentation agent in the field.

|

Aliphatic and aromatic hydrocarbons are typically present in contaminated soils in the form of total petroleum hydrocarbons (TPH), often in combination with carcinogenic polycyclic aromatic hydrocarbons (PAHs) (e.g. anthracene, phenanthrene, benzopyrene).

Our Ferm&Go 2PT product contains hydrocarbon-degrading microorganisms such as Lelliottia jeotgali, Pseudomonas mandelii, Rhodococcus qingshengii with a cell count values at least 10E9/ ml. |

|

Our Ferm&Go 3P microbial inoculum mainly used for the degradation of PAH – polycyclic aromatic hydrocarbons and the associated TPH – aliphatic hydrocarbon contaminants. The product contains hydrocarbon-degrading microorganisms such as Cupravidus necator, Pseudomonas benzenivorans, Pseudomonas extremaustralis with a cell count values at least 10E9/ml.

|

The ability to degrade aliphatic, aromatic and polyaromatic hydrocarbons are widespread among the microorganisms. Various groups of bacteria and fungi are characterized with hydrocarbon-degradation potential, however, none of the microorganisms are capable to degrade the whole spectrum of this highly diverse group of compounds, therefore, diverse microbial communities characterized with different enzyme system are suitable for the complete degradation of complex contaminants.

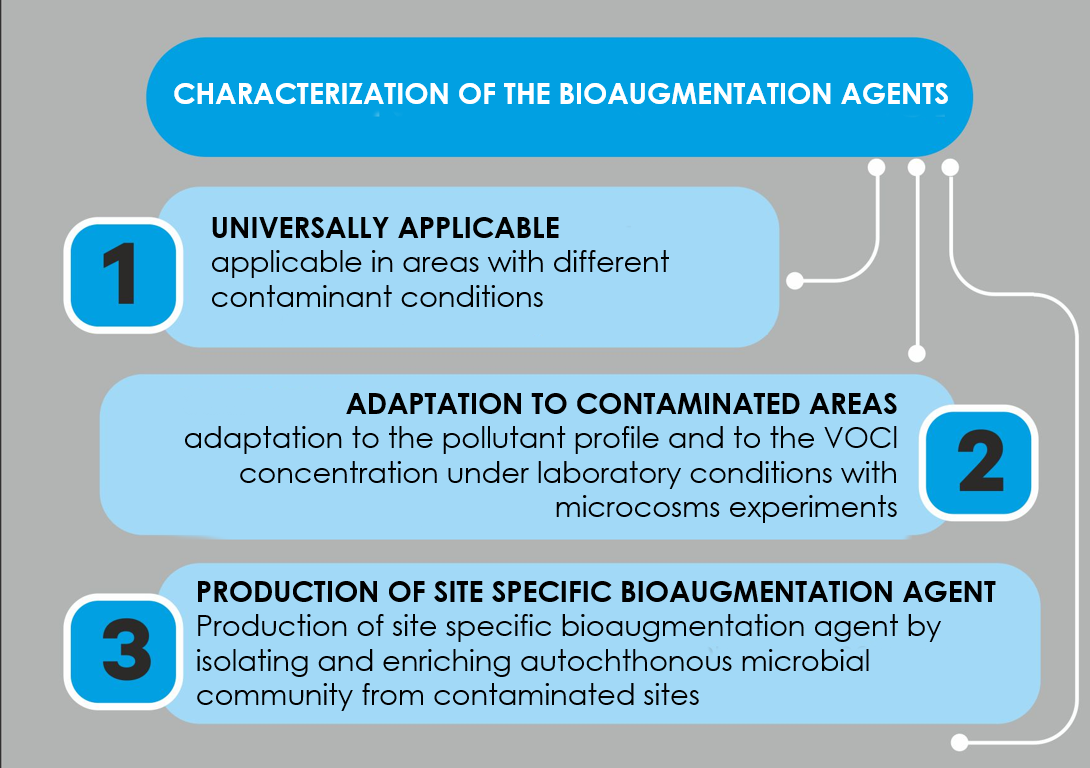

The most effective solution to degrade complex contaminants is the application of microorganisms and/or microbial communities originated from contaminated sites. The application of predominately autochthonous microbial community adapted to certain pollution and environmental conditions (physico-chemical properties) has a greater chance of being effective, i.e. the use of site specific bioaugmentation agent. The major advantage of a site-specific microbial inoculum is that microorganisms derived from and returned to one site can result in a significant reduction in contaminants, although bioaugmentation products containing allochthonous microorganisms may not be sufficiently effective in all contaminated areas.

In bioremediation, applying a bioaugmentation agent containing an effective microbial community adapted to local parameters is a half-success.

For the development of site-specific bioaugmentation agent, enrichment cultures and microcosms (ecosystem selection systems) were prepared using contaminated soils and groundwater to isolate and enrich microorganisms and microbial communities capable of hydrocarbon degradation. During the development and production process, changes in the concentration of the contaminant, i.e. biological degradation of the contaminant and the alteration of the microbial community, are monitored by gas chromatography (GC/GC-MS) and molecular biology methods (PCR, quantitative PCR, sequencing, microbial community analyses), respectively, to ensure excellent product quality. The site-specific bioaugmentation agents developed are produced in our fermenter park with a capacity of over 4500 litres.

Although the development of site-specific inocula is time and energy intensive, it provides an opportunity for effective remediation. The time required for remediation can be significantly reduced by adding biostimulation agents (e.g. application of carbon, nitrogen sources, electron donors, acceptors).

In bioremediation, applying a bioaugmentation agent containing an effective microbial community adapted to local parameters is a half-success.

For the development of site-specific bioaugmentation agent, enrichment cultures and microcosms (ecosystem selection systems) were prepared using contaminated soils and groundwater to isolate and enrich microorganisms and microbial communities capable of hydrocarbon degradation. During the development and production process, changes in the concentration of the contaminant, i.e. biological degradation of the contaminant and the alteration of the microbial community, are monitored by gas chromatography (GC/GC-MS) and molecular biology methods (PCR, quantitative PCR, sequencing, microbial community analyses), respectively, to ensure excellent product quality. The site-specific bioaugmentation agents developed are produced in our fermenter park with a capacity of over 4500 litres.

Although the development of site-specific inocula is time and energy intensive, it provides an opportunity for effective remediation. The time required for remediation can be significantly reduced by adding biostimulation agents (e.g. application of carbon, nitrogen sources, electron donors, acceptors).